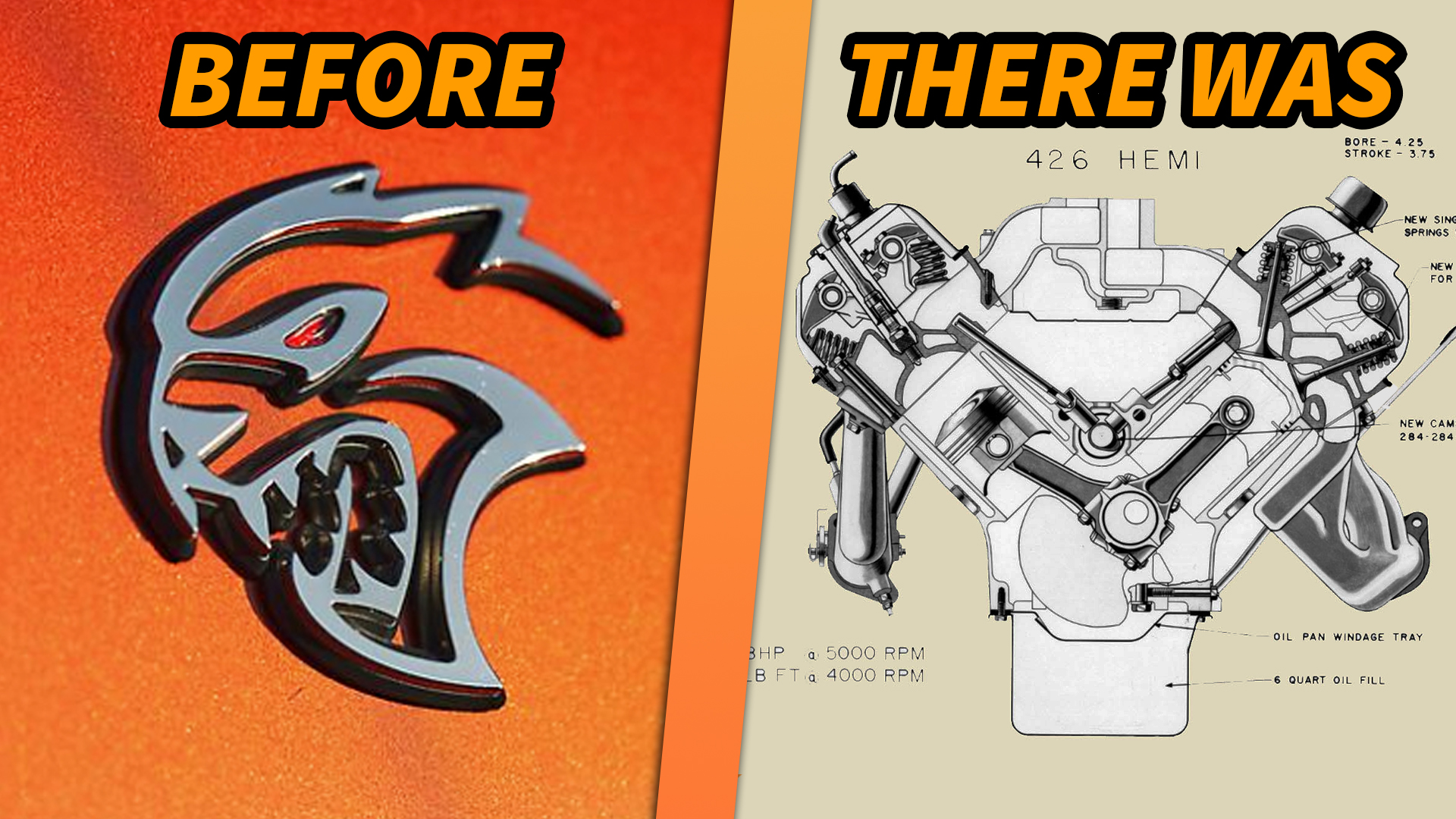

Being raised on Mopar guarantees two things. One, you have a big chip on your shoulder because Ford and Chevy get all the love. Two, the Hemi is the grease-covered idol you pray to every night. But the Hemi engine's story is one of glory and banishment.

Throughout its life, the Hemi regularly found itself on the outs. Whether it was on account of being too big, too fast, or having the rules bent against it, the Hemi had a habit of looking like a wild animal in an antique store. That perceivable personality is, of course, a huge part of the engine’s appeal. Hemis powered some cars that were sold with cartoon character stickers from the factory—that says a lot about the wacky energy the company was channeling. Its demise truly is the end of an era, as Dodge turns its attention to other means of propulsion for its legendary muscle cars.

"The Dodge Challenger and Charger are coming to an end in their current Hemi-engine-powered forms at the end of 2023. The next generation of Dodge muscle car will be a new, high-performance electric vehicle" says Dodge in an exclusive statement. Though it’s since been confirmed that the Dodge Charger will live on with an optional gas engine, a Hemi is not the powerplant of choice— at least as far as we know.

As funny as it seems, the many unjust deaths of the Hemi are part of what makes it so special. So, while the news may bog us down for a moment, it's something Dodge fans are accustomed to. All we can do is look back and admire the tragedy and triumph that is the Hemi.

www.thedrive.com

www.thedrive.com

Throughout its life, the Hemi regularly found itself on the outs. Whether it was on account of being too big, too fast, or having the rules bent against it, the Hemi had a habit of looking like a wild animal in an antique store. That perceivable personality is, of course, a huge part of the engine’s appeal. Hemis powered some cars that were sold with cartoon character stickers from the factory—that says a lot about the wacky energy the company was channeling. Its demise truly is the end of an era, as Dodge turns its attention to other means of propulsion for its legendary muscle cars.

"The Dodge Challenger and Charger are coming to an end in their current Hemi-engine-powered forms at the end of 2023. The next generation of Dodge muscle car will be a new, high-performance electric vehicle" says Dodge in an exclusive statement. Though it’s since been confirmed that the Dodge Charger will live on with an optional gas engine, a Hemi is not the powerplant of choice— at least as far as we know.

As funny as it seems, the many unjust deaths of the Hemi are part of what makes it so special. So, while the news may bog us down for a moment, it's something Dodge fans are accustomed to. All we can do is look back and admire the tragedy and triumph that is the Hemi.

Ode to the Hemi: A Look Back at the Legacy of Death and Glory

As Dodge prepares to pull the plug on the Hemi in cars, we take a look back on all the times it wound up on the wrong side of the rulebook.